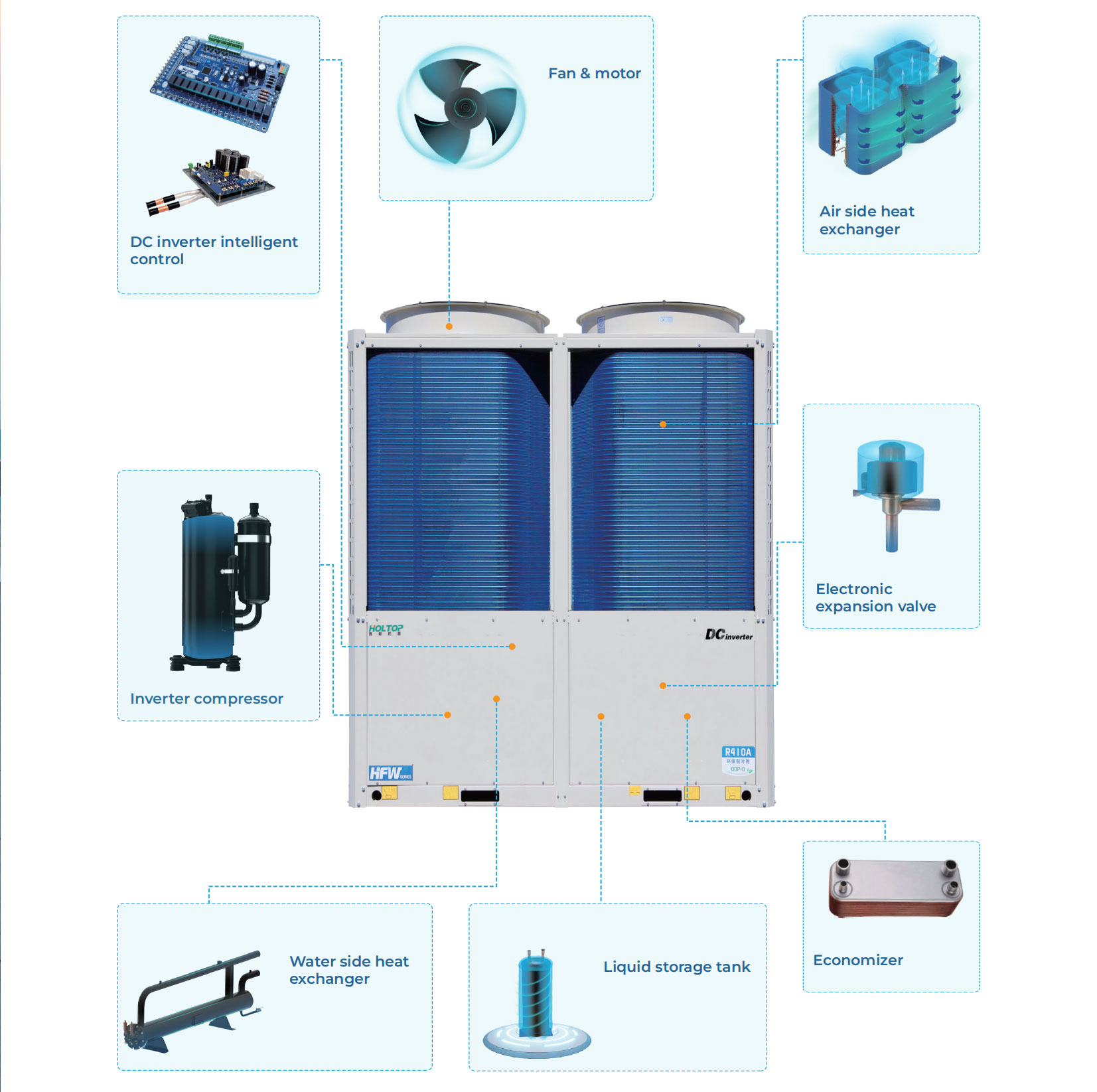

DC Inverter Heat Pump Air Cooled Scroll Chiller

Sophisticated Design

| DC inverter intelligent control | The variable frequency module PCB control board, developed in collaboration with Holtop and manufacturers of compressors, valves, and controllers, ensures stable operation, advanced logic, and multiple protections, safeguarding the entire air conditioning system. |

| Fan & motor | Adopt large air volume, low noise fan impeller with low rotation speed and high efficiency motor. |

| Air side heat exchanger | The design of ring type air inlet heat exchanger makes the air distribution more uniform and the heat exchange more adequate. |

| Inverter compressor | DC inverter technology offers a high degree of adjustment, making the air conditioning system more comfortable and energy efficient. |

| Electronic expansion valve | Precise throttling control of the 480-step electronic expansion valve to keep the unit running at the optimal energy efficiency |

| Water side heat exchanger |

Shell and tube heat exchanger with new spiral baffle technology is about to increase efficiency of 10%.

|

|

Liquid storage tank

|

Large volume and low pressure loss liquid storage tank to ensure the system runs more reliably

|

|

Economizer

|

To ensure effective subcooling of the refrigerant, a stainless steel brazed plate heat exchanger is utilized.

|

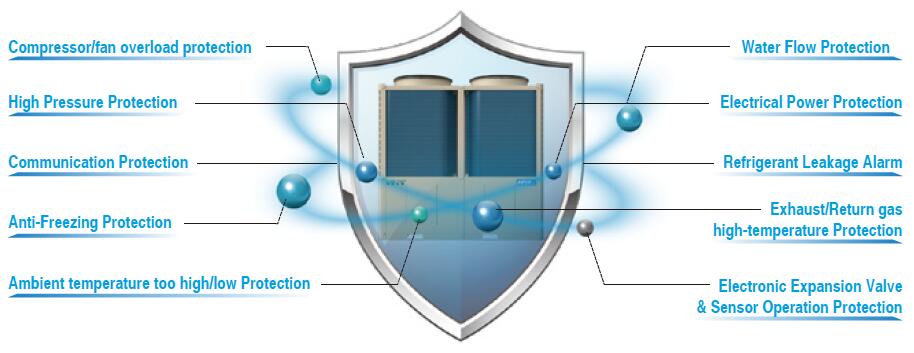

RELIABLE OPERATION

Integrated Protection

Designing more than 10 safety protection functions, which can ensure chiller unit and the system operation in all-round protection. The unit can be controlled through a multi-variable monitoring system to ensure the unit with stable and efficient operation.

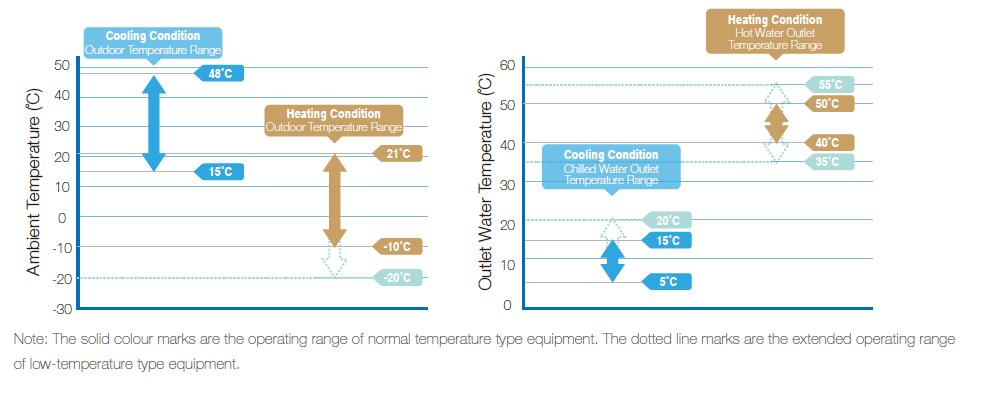

Wide Temperature Range of Application, Worry-free of Operation

Chiller unit is suitable for operation in a wide outdoor temperature range, from -20˚C~48˚C.

Note: The solid colour marks are the operating range of normal temperature type equipment. The dotted line marks are the extended operating range of low-temperature type equipment.

Chiller Unit Operation When Has Fault

A single unit is designed with multiple compressors. When one of the compressors fails, the rest of the compressors in the system can still operate normally without affecting the operation of the whole system.

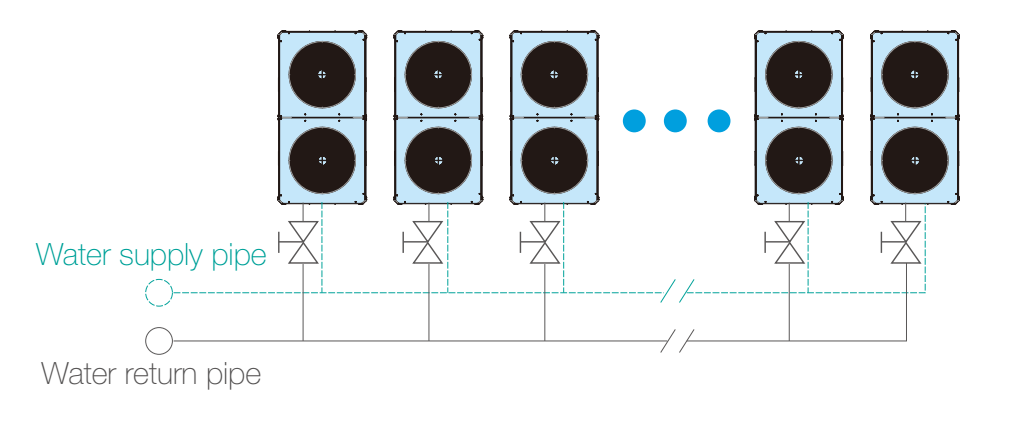

MODULAR COMBINATION

The chiller adopts modular combination design and does not need to set the master or sub-mater unit. Each combination is able to connect a maximum of 16 units, even they are made of different models, to meet the variable demands of different buildings.

Steps Starting

Starting all units in steps, in order to lower the starting current, reduce the shock to power grid, and avoid affecting the security of other electrical equipment.

Flexible Application

Investment: Add extra units into combination at any time, convenient for multiple stages of investment.

Transportation: The volume of each unit is compact, can be transported individually, does not need a crane at the project site, can save transportation cost.

Installation: Does not need machine room or cooled water system, only somewhere with good ventilation. The water pipes are designed on side of the unit, which can be easy for chilled water connection and save installation space.

System: At the water circulating system, besides the standard use of the constant flow system, it is optional to use the primary pump with a variable flow system, and the variable speed control cabinet is optional to select.

Smart Defrosting System

By sensing with the multi-variables system to have accurate judgement on the situation of frosting, the chiller itself can be able to choose the best time to enter or exit defrosting, to avoid insufficient defrosting or over defrosting. In a duplex system, the units can achieve alternate defrosting. When heating under extreme low-temperature conditions, setting manual defrosting for better performance.

INTELLIGENT CONTROL

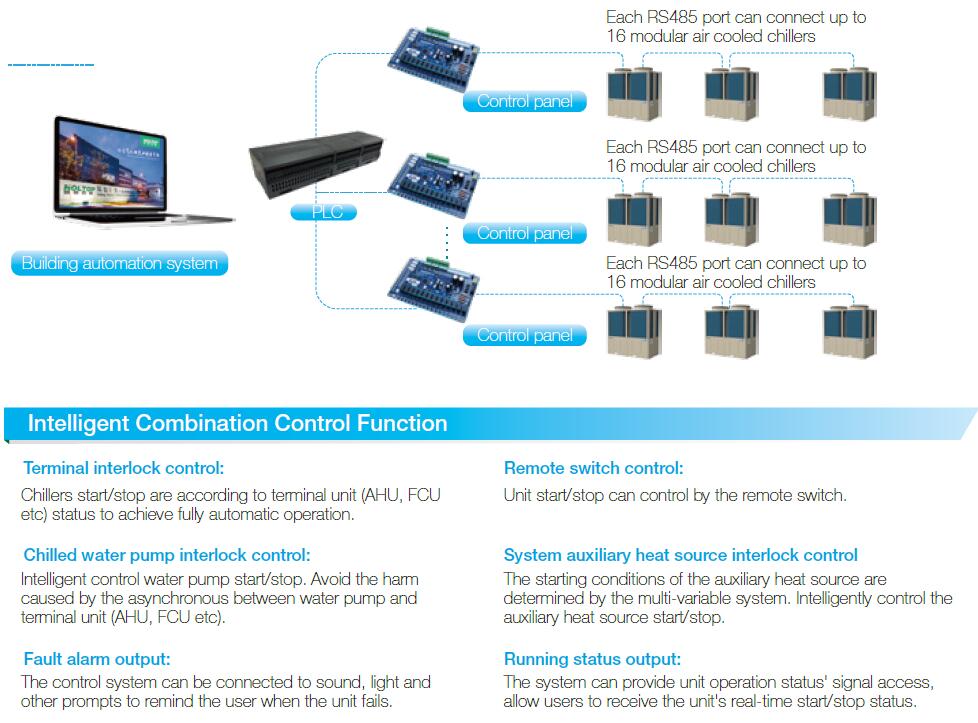

Intelligent PLC Control System:

The PLC control system combines the simplicity and convenience of the wired control system and the advantages of the centralized group control system to achieve chiller group centralized control. One PLC control system can manage 1 to 8 groups. Each group can control 1 to 16 pieces of modular chillers. The system can control up to 128 modular chillers. The control system also delivers various features such as group mode switching, temperature adjustment, on/off control, etc to adopt numerous applications.

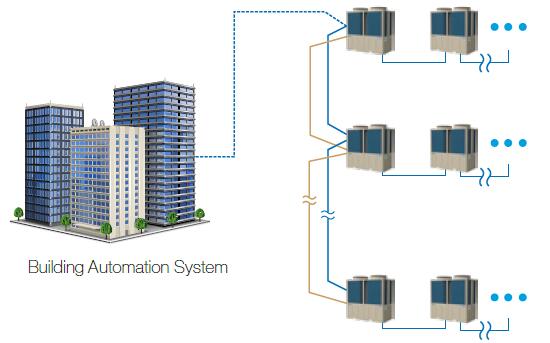

Free Access to Building Automation System:

Standard RS485 building communication interface comes with open access to standard ModBus communication protocol. The device can be easily connected to the building control system (BAS) for centralized control, easy to achieve intelligent control, avoid unnecessary energy waste, and save air-conditioning operating costs.

Introduction video of Modular Air Cooled Chiller Heat Pump. Please follow Holtop YouTube channel to get latest update.

Single Room Heat Recovery Ventilator

Hrv Heat Recovery Ventilator

Ductless Heat Recovery Ventilator

Heat Recovery Ventilators

commercial heat recovery ventilator