OEM Factory for Evaporator Coil Cooler - Total Heat Exchanger – Holtop

OEM Factory for Evaporator Coil Cooler - Total Heat Exchanger – Holtop Detail:

Working Principle of Holtop Crossflow Plate Fin Total Heat Exchangers (E.R. Paper for enthalpy exchange core)

| The flat plates and the corrugated plates form channels for fresh or exhaust air stream.

When the two air steams passing through the exchanger crossly with temperature difference, the energy is recovered. |

|

Main features

1. Made of E.R. paper, which is featured by high moisture permeability, good air tightness, excellent tear resistance, and aging resistance.

2. Structured with flat plates and corrugated plates.

3. Two air streams flow crossly.

4. Suitable for room ventilation and industrial ventilation system.

5. Heat recovery efficiency up to 70%

| Gas molecules type | Carbon dioxide (CO2) | Ammonia (NH3) | Methane (CH4) | Vapor(H2O) | The clearance of fiber |

| Diameters(nm) | 0.324 | 0.308 | 0.324 | 0.288 | 0.3(for reference) |

Application

Used in comfortable air conditioning ventilation system and technical air conditioning ventilation system. Supply air and ex- haust air totally separated, heat recovery in winter and cold re- covery in Summer

Specifications

| Model | A (mm) | L (mm) | C (mm) | Optional corrugation height (mm) | Remarks |

| HBT-W168/168 | 168 | ≤500 | 240 | 2.0, 2.5 |

One module |

| HBT -W202/202 | 202 | ≤500 | 288 | 2.0, 2.5 | |

| HBT -W222/222 | 222 | ≤500 | 317 | 2.0, 2.5 | |

| HBT-W250/250 | 250 | ≤700 | 356 | 2.0, 2.5, 3.5 | |

| HBT-W300/300 | 300 | ≤700 | 427 | 2.0, 2.5, 3.5 | |

| HBT -W350/350 | 350 | ≤700 | 498 | 2.5, 3.5 | |

| HBT -W372/372 | 372 | ≤700 | 529 | 2.5, 3.5 | |

| HBT -W400/400 | 400 | ≤700 | 568 | 3.5 | |

| HBT -W472/472 | 472 | ≤550 | 670 | 3.5 | |

| HBT -W500/500 | 500 | ≤550 | 710 | 3.5 | |

| HBT -W552/552 | 552 | ≤550 | 783 | 3.5 | |

| HBT -W600/600 | 600 | ≤550 | 851 | 3.5 | |

| HBT -W652/652 | 652 | ≤550 | 925 | 3.5 | |

| HBT -W700/700 | 700 | ≤550 | 993 | 3.5 | Multi-modulecombined |

| HBT -W800/800 | 800 | ≤550 | 1134 | 3.5 | |

| HBT-W1000/1000 | 1000 | ≤450 | 1417 | 3.5 | |

| HBT-W1200/1200 | 1200 | ≤450 | 1702 | 3.5 | |

| HBT -W1400/1400 | 1400 | ≤450 | 1985 | 3.5 | |

| HBT -W1600/1600 | 1600 | ≤450 | 2265 | 3.5 |

Product detail pictures:

Related Product Guide:

Fluid Air Heat Exchangers Market Demand and Growth Opportunities 2018-2023 | Silent Ventilation Fan

When to Inspect and Clean Your Heating, Ventilating and Air Conditioning System

We are experienced manufacturer. Wining the majority of the crucial certifications of its market for OEM Factory for Evaporator Coil Cooler - Total Heat Exchanger – Holtop, The product will supply to all over the world, such as: Brisbane, Belgium, Malaysia, Our products have won an excellent reputation at each of the related nations. Because the establishment of our firm. we have insisted on our production procedure innovation together with the most recent modern day managing method, attracting a sizable quantity of talents within this industry. We regard the solution good quality as our most vital essence character.

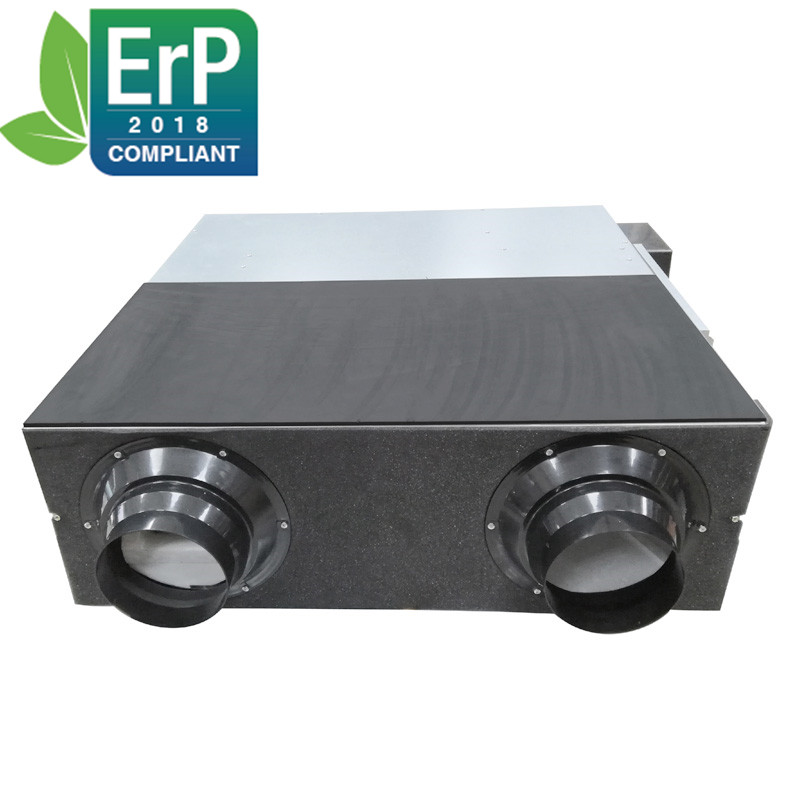

Heat Recovery Ventilator

Hrv Heat Recovery Ventilator

Ductless Heat Recovery Ventilator

Single Room Heat Recovery Ventilator

Heat Recovery Ventilators

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.