China Supplier Neoprene Beer Tube Coolers - Heat Wheels – Holtop

China Supplier Neoprene Beer Tube Coolers - Heat Wheels – Holtop Detail:

Rotary heat exchanger (wheel) is mainly used in building ventilation or in the air supply/discharge system of air conditioning equipment. The wheel transfers the energy (cold or heat) contained in exhaust air to the fresh air supplied to indoor. It’s one important equipment and key technology in the field of construction energy-saving.

Rotary heat exchanger is composed of heat wheel, case, drive system and sealing parts. The heat wheel rotates powered by the drive system. When outdoor air passes through half of the wheel, return air passes through reversely the rest half of the wheel. In this process, about 70% to 90% heat contained in the return air can be recovered to supply air to indoor.

Working Principle

Rotary heat exchanger is composed of alveolate

heat wheel, case, drive system and sealing parts.

The exhaust and outdoor air pass through half of the

wheel separately, when the wheel rotates, the heat

and moisture are exchanged between the exhaust and

outdoor air. The energy recovery efficiency is up to

70% to 90%

| Sensible Wheel Materials

The sensible heat wheel is made by aluminum foils of 0.05mm thickness. |

|

| Wheel Construction The wheel of the rotary heat exchanger is made of alternating layers of flat and corrugated aluminum foil to form the alveolate shape. Various height of corrugation is available. Flat surface ensures minimum leakage. Interior spokes are used to mechanically bond the rotor’s laminations. These are threaded at the hub and welded at the periphery.

|

|

| Applications Rotary heat exchanger can built in air handling unit (AHU) as a main part of the heat recovery section. Usually side panel of the exchanger casing is unnecessary, except that bypass has been set in AHU. |

|

|

|

| It can also be installed in the ducts of ventilation system as a main part of the heat recovery section, connected by flange. In this case, side panel of the exchanger is necessary to prevent leakage.  |

|

| Note: casing type and segment quantity should depend on the application spaces as well as transportation capability and conditions at installation. Over segmentation will increase the assembly work, and overlarge size will cause diffculties in transportation. Application conditions: - Ambient temperature: -40-70°C - Max face velocity: 5.5m/s - Max pressure on casing: 2000Pa |

|

Product detail pictures:

Related Product Guide:

Global Embedded System Market Report 2018-2025 with Profiles of Major Manufacturers (Renesas Electronics, STMicroelectronics, NXP(Freescale)) – Press Release | Whole House Air Exchanger

Challenges of Proper Air Ventilation | Air Heat Exchangers

With this motto in mind, we have turn out to be amongst probably the most technologically innovative, cost-efficient, and price-competitive manufacturers for China Supplier Neoprene Beer Tube Coolers - Heat Wheels – Holtop, The product will supply to all over the world, such as: Ecuador, US, Borussia Dortmund, With excellent solutions, high quality service and sincere attitude of service, we ensure customer satisfaction and help customers create value for mutual benefit and create a win-win situation. Welcome customers all over the world to contact us or visit our company. We'll satisfy you with our qualified service!

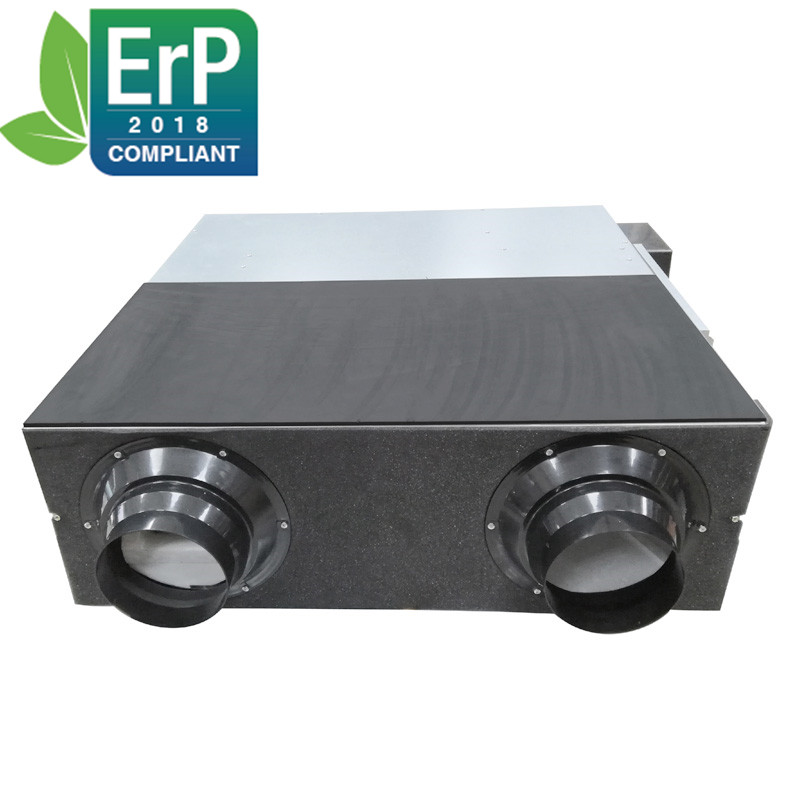

Hrv Heat Recovery Ventilator

Ductless Heat Recovery Ventilator

Heat Recovery Ventilator

Heat Recovery Ventilators

commercial heat recovery ventilator

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.