Water have been used to cool and heat air in finned-tube heat exchange coils almost since the inception of heating and air conditioning. Freezing of the fluid and the resultant coil damage have also been around for the same length of time. It is a systematic problem that many times is preventable. In this article, we listed a few tips that help you prevent the frozen crack coil in winter.

- If the unit is not operating during winter, all the water in the system must be released to prevent coil crack.

- For emergency situation such as power outage or electricity maintenance, the air damper should closed immediately to ensure no outside air enter the system. Fluid is not being pumped through the coil and dropping temperature inside AHU may cause ice formation. The temperature inside the AHU should keep above 5 ℃.

- Cleaning Coil and water filter regularly. Objects stuck in pipeline causing poor water circulation. Liquid trap in the coil tube resulting coil damage when the freeze condition is present.

- Improper control system design. Some control systems only adjust the water valve’s opening not fan speed based on indoor temperature controller. Lack of fan control resulting weak water circulation and high air volume, causing frozen water in coil. (The standard water velocity in coil should be controlled at 0.6~1.6m/s)

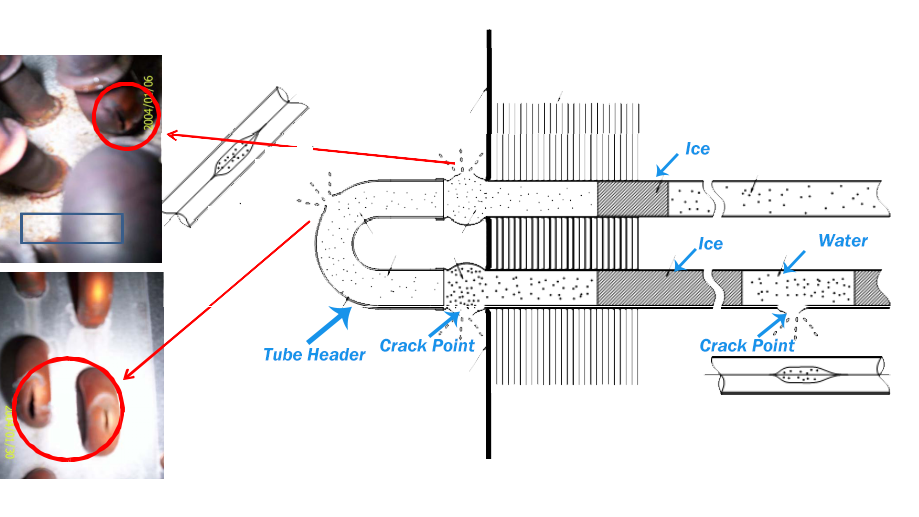

The circuitry of the coil where the pressure builds, and the weakest point in that circuit. Extensive testing has shown that the failure will appear as a bloated area in the tube header or bend that has expanded. In most cases, is the area that will rupture.

Please see below for the pressure calculation due to the frozen coil.

P=ε×E Kg/cm2

ε = Increasing Volume (Condition: 1 atmospheric pressure, 0℃,volume of 1 kg water)

ε = 1÷0.9167=1.0909 (9% Volume increase)

E= modulus of elasticity in tension (Ice = 2800 Kg/cm2)

P=ε×E=(1.0909-1)×2800=254.5 Kg/cm2

Adverse pressure is the cause of freeze damage to a coil. Coil damage due to a liquid line freeze relates to the extreme pressure produced during the formation of ice. The area that contains this ice can only handle this added pressure until it reaches a limit that causes heat exchanger damage and subsequent failure.

If you have any questions regarding air handling unit winter protection, contact us!

Post time: Jan-15-2021