As new building codes standards lead to tighter building envelopes, homes are requiring mechanical ventilation solutions to keep the indoor air fresh.

The simple answer to the headline of this article is anyone (human or animal) living and working indoors. The larger question is how we go about providing enough fresh oxygenated air for building inhabitants while maintaining reduced levels of HVAC energy consumption as prescribed by current governmental regulations.

Inspired by the fall-out of an oil embargo in the early 1970s, the U.S. Department of Energy (DOE) embarked on an all-encompassing energy security program that led to North American regulators developing ever-increasing HVAC efficiency standards or Minimum Efficiency Performance Standards (MEPS).

Along with more energy-efficient HVAC appliances another trend has led to sealing houses up as tight as possible with tight-fitting windows, doors, vapour barriers and cans of expanding foam insulation.

In one study of a 90’s era residential renovation, the house in question was depressurized beyond 50 pascals once all the air exhausting appliances (bathroom fans, kitchen range hood) were running. That’s 10 times more depressurization than allowed, especially with buoyancy vented fossil-fueled appliances inside the structure. We need air!

What Kind of Air?

With today’s tighter building envelopes we need to consider how to introduce air inside and why. And we might need several kinds of air. Normally there’s only one type of air, but inside a building we need the air to do different things depending on our indoor activities.

Ventilation air is the most important kind for humans and animals. Humans respire some 30 lbs. of air daily while we spend almost 90% of our lives indoors. At the same time, it is necessary to get rid of excess moisture, odours, carbon dioxide, ozone, particulates and other noxious compounds. And while opening a window provides needed ventilation air, this unregulated ventilation will cause HVAC systems to consume excessive amounts of energy—energy we’re supposed to be saving.

Make-up air is the air coming in from outside intended to replace that air being exhausted by devices such as range hoods and bathroom fans, central vacuum systems and clothes dryers. Today’s homes built to the latest codes probably do not need make-up air anymore unless oversized range hoods moving large air volumes (more than 200 cfm) are installed by overzealous chefs.

Finally, there is also combustion air, the air meant to be used with fossil-fueled appliances such as gas furnaces, water heaters, stoves and wood burning fireplaces. By filling every conceivable air leakage gap in today’s homes, gas appliances must “borrow” ventilation air thus creating a dangerous problem. Appliances unable to vent due to depressurization, or starved for air, could start to burn their own flue products creating deadly carbon monoxide, a tragedy that has ended the lives of too many people over the years.

Introducing HRV and ERV

Older buildings were so leaky that infiltrating air met all the ventilation requirements with ease, but not without penalties. Incoming air needed to be conditioned with heat and maybe humidity incurring extra costs for fuel and maintenance. Houses were drafty, occupants often felt uncomfortable as dry air evaporated excessive amounts of moisture from the skin creating a feeling of being too cold. Static electricity build-up in carpets and furnishing caused painful shocks when the electrically charged homeowner touched a grounding surface. So, which is better?

A heat recovery ventilator (HRV) is a mechanical ventilation solution that will use the stale exhaust airstream to preheat the same volume of cold entering outdoor fresh air.

As the airstreams pass each other within the core of the HRV, upwards of 75% or better of the indoor air heat will be transferred to the colder air thus providing needed ventilation while reducing the cost of “making up” the heat required to bring that fresh air up to ambient room temperature.

In humid geographies, in the summer months an HRV will increase the humidity level in the house. With a cooling unit in operation and the windows closed, the house still needs adequate ventilation. A properly sized cooling system designed with the summer latent load in mind should be able to deal with the extra humidity, admittedly, at an extra cost.

An energy recovery ventilator (ERV), operates in a similar fashion to the HRV, but during the winter some of the humidity in the air is returned to the indoor space. Ideally, in tighter houses, an ERV will help to retain indoor humidity in the 40% range countering the uncomfortable and unhealthful effects of dry wintertime air.

Summer operation has the ERV reject as much as 70% of the incoming humidity sending it back outside before it can load-up the cooling system. An ERV does not act as a dehumidifier.

ERV’s Are Better for a Humid Climate

Ventilation experts will say the ideal mechanical ventilation unit for any home is dependent on the local climate, lifestyle of the occupants and the owner’s specific needs. For example, in houses where the wintertime humidity level tends to rise above 55%, an HRV would do a better job of removing excess humidity.

Experts also agree that newer houses, or those renovated to the latest building code, should have an ERV specified since buildings equipped with triple glazed windows and properly insulated basements can support a higher relative humidity in the winter months: 35% +/- 5% is acceptable.

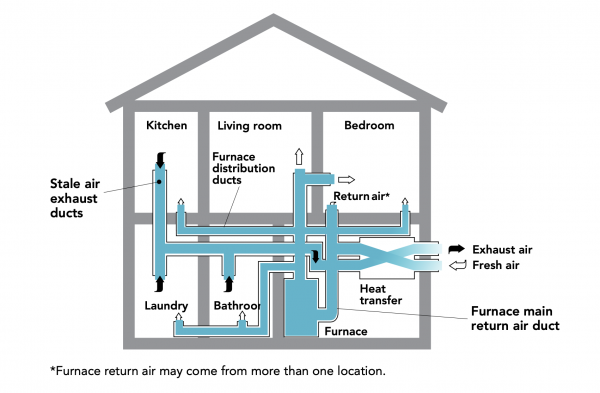

Example diagram of an HRV installed with a forced air furnace system. (source: NRCan Publication (2012): Heat Recovery Ventilators)

Installation Considerations

While ERV/HRV units designed for residential installation can be installed in a simplified fashion using the existing air handling system to distribute the conditioned air, do not do it that way if possible.

In my opinion, it is best to install a fully dedicated duct system in new construction or complete renovation jobs. The building will benefit from the best possible conditioned air distribution and the lowest possible operating cost, as the furnace or air handler fan will not be needed.

Some of the best HRV/ERV equipment on the market feature EC motors and control algorithms capable of automatically balancing the systems and adapting to pressure changes.

It may take some time to convince all homeowners that mechanical ventilation is truly superior to open windows at any time. Urbanites truly have a vested interest in relying upon professionally installed and well-maintained mechanical ventilation, something, as studies suggest, they have never had before.

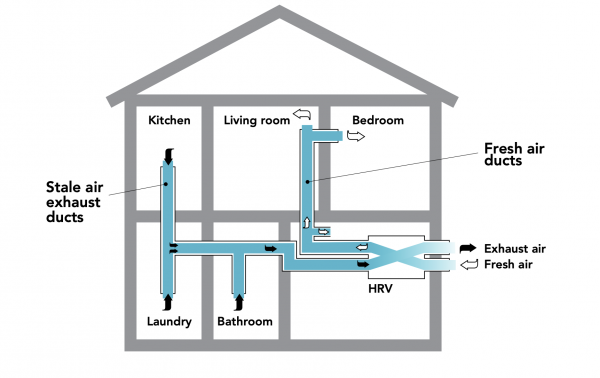

Example of an HRV installation with direct ductwork. (source: NRCan Publication (2012): Heat Recovery Ventilators)

Holtop is the leading manufacturer in China specializing in the production of air to air heat recovery equipments. It is dedicated to the research and technology development in the field of heat recovery ventilation and energy saving air handling equipments since 2002. The main products includes energy recovery ventilator ERV/HRV, air heat exchanger, air handling unit AHU, air purification system. Besides, Holtop professional project solution team can also offer customized hvac solutions for different industry.

Below are some the related products, please contact us if you are interested in any of our HRV/ERV/Heat exchanger products.

For more information, please visit: https://www.hpacmag.com/features/ventilation-who-needs-it/

Post time: Mar-17-2022